Material

- It can be rigid, soft, or somewhere in between.

- It can be thin or thick.

- It can be light or heavy.

- It allows maximum freedom in the design phase: variable thicknesses, complex shapes and undercuts.

- It can be reinforced with inserts.

- It is inert to many substances. It is water resistant.

- It is highly insulating.

- It has excellent mechanical characteristics.

- It can be worked on using the most common wood tools.

- It can be printed, and the moulds are very convenient.

- It can be painted.

Rigid 40/80kg/m3

an ideal polyurethane for thermal insulation, it is used for insulation

- thermal conductivity of 19 to 25 mW/mK

Rigid 200/250kg/m3

a good compromise between thermal conductivity and structural rigidity, suitable for producing technical refrigeration components

- surface hardness from 20 to 45 Shore D

- compressive strength from 300 to 400 KPa

- insulation with a thermal conductivity of 19 to 41 mW/mK

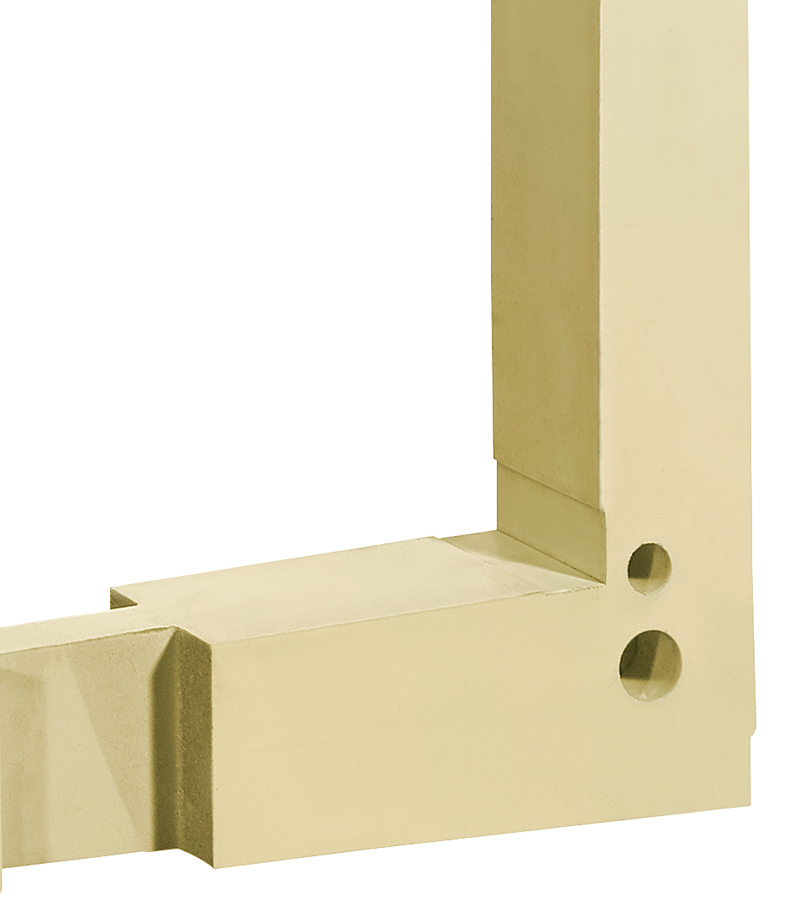

Rigid 400/600kg/m3

a polyurethane with a density similar to wood, suitable for aesthetic details (painted)

- surface hardness from 50 to 80 Shore D

- insulation with a thermal conductivity of 19 to 70 mW/mK

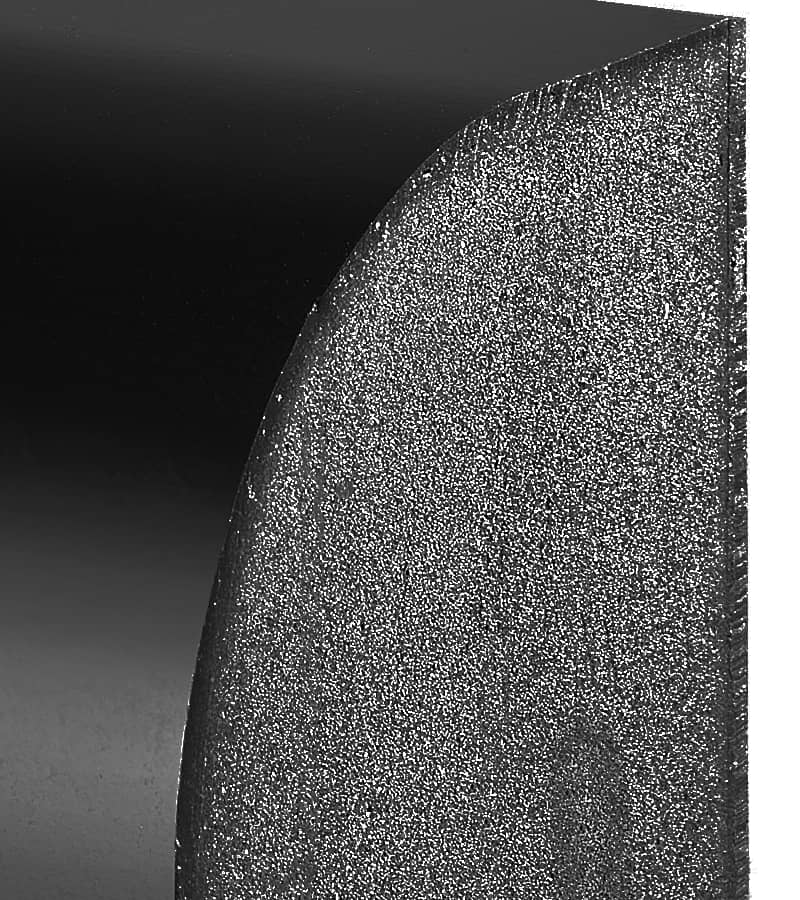

Rigid 1,000kg/m3

a rigid structural polyurethane that allows for the creation of very thin and resistant items

- Flexural modulus 2000 MPa

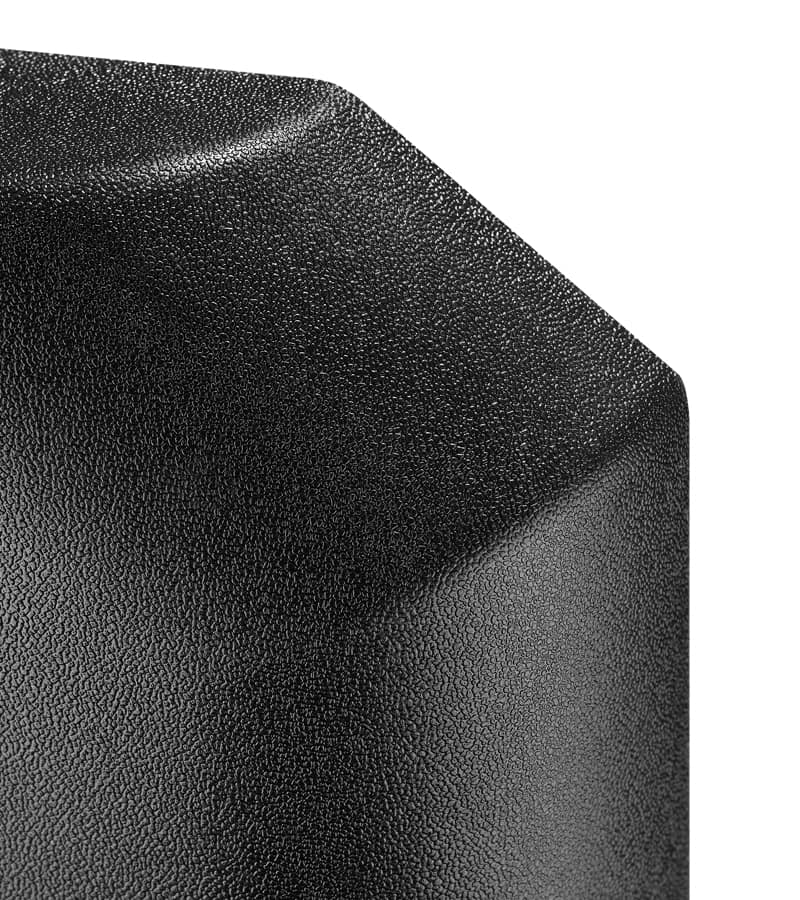

RIM/density 1,000kg/m3

a polyurethane that is more flexible than rigid polyurethane, suitable for making bumpers, for example

- Flexural modulus 450 MPa

- surface hardness from 55 to 65 Shore D

- elongation 70%

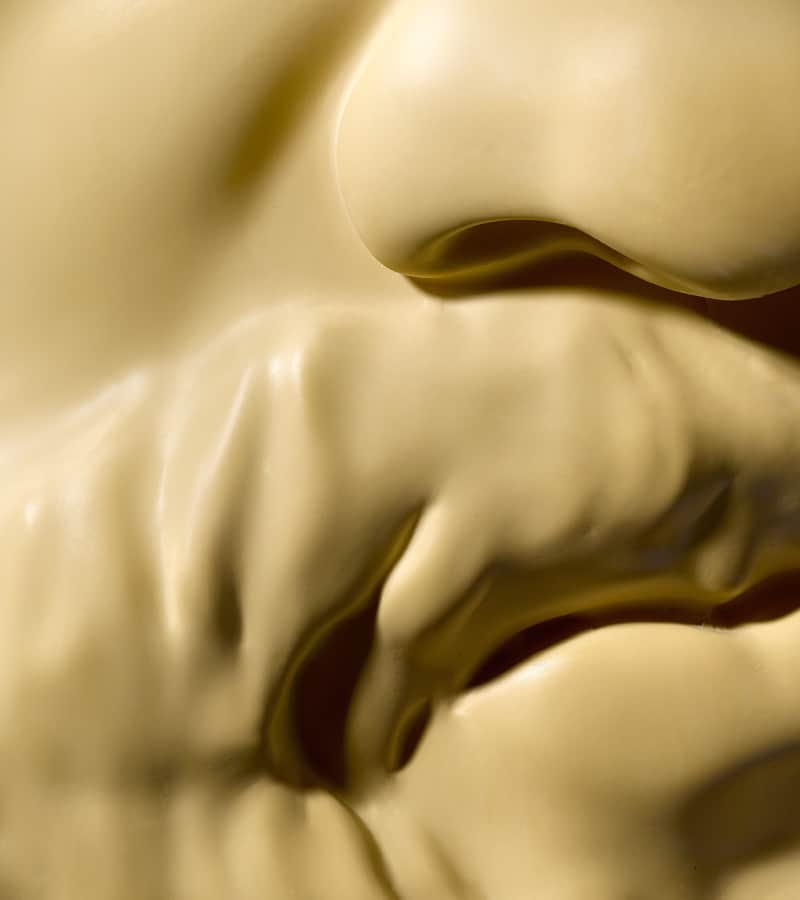

Integral

an “elastic” polyurethane, characterised by its resistant outer layer and expanded core – it offers varying degrees of softness

- surface hardness from 30 to 70 Shore D