With over 30 years experience in the refrigeration industry, we’ve well and truly honed our specialised and qualified skills.

Polyurethane is an excellent material for the refrigeration sector: it’s insulating, resistant to humidity, can accommodate structural reinforcement and can also be used to create complex geometric shapes.

In addition to producing all the traditional polyurethane elements you find in refrigeration units, we’ve also designed and developed a technology dedicated to this particular product sector: PUR 3D® Sandwich Technology, an innovative process that combines the very best features of polyurethane with sandwich panels.

Refrigeration

PUR 3D sandwich technology – High efficiency in one single solution

“efficiency by design”

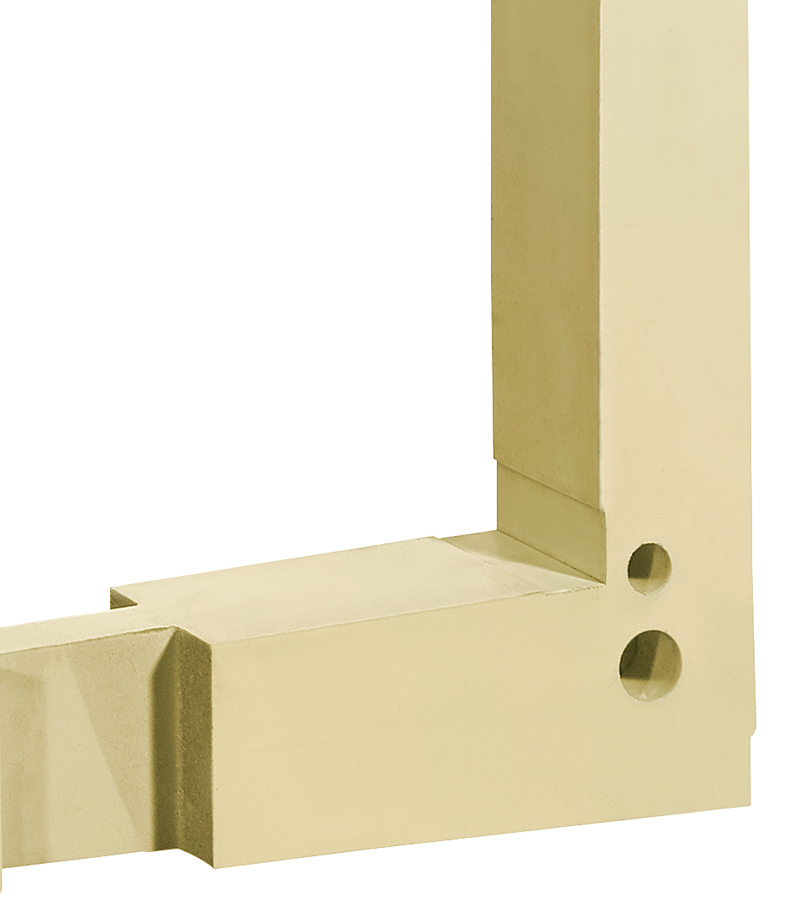

PUR 3D allows for considerable optimisation in the refrigeration market. In fact, we can replace metal parts and components with polyurethane (metal replacement), freeing designers from the constraints of working with sheet metal.

PUR 3D allows you to design components that increase refrigeration unit production line efficiency, it’s also lighter (lightweight) and allows us to contribute to the industrialisation of the refrigeration sector.

Technical features:

- high-thermal insulation

- lightweight and strong

- excellent adhesion between core and outer layer

- simplifies end-of-life treatments (no different material layers, it’s only polyurethane)

- option to embed metal inserts, to reinforce the product or to create quick attachment points

- can be painted

- option to create sharp edges

- option to create variable thicknesses

- excellent geometric tolerance

The outer layer is made from compact polyurethane, measuring up to 1150kg/m3. The outer layer thickness can vary depending on various sector needs, but typically measures from 0.5 to 3mm.

Different types of polyurethane can be used for the core. Low-density polyurethane (from 50 kg/m3 up) guarantees excellent thermal insulation.

+ = yes | – = no | o = possible but not recommended

TECHNOLOGY

This technology makes it possible to create parts with a high-density polyurethane outer layer and a low-density polyurethane core.

Combining these two different materials creates both a rigid and lightweight structure, similar to traditional sandwich panels but with a revolutionary design.

PUR 3D allows you to design with greater freedom thanks to its variable core thickness, variable outer layer thickness, 3D surfaces, sharp and rounded edges, and the option to embed complex inserts.

What could previously only be achieved with the use of multiple components can now be integrated into a single component, resulting in cost savings, a simplified logistics chain, a reduced assembly time and a smaller lead time.

In order to achieve our goals, we design components together with our customers, sharing detailed information about our technology and providing support during the design phase.

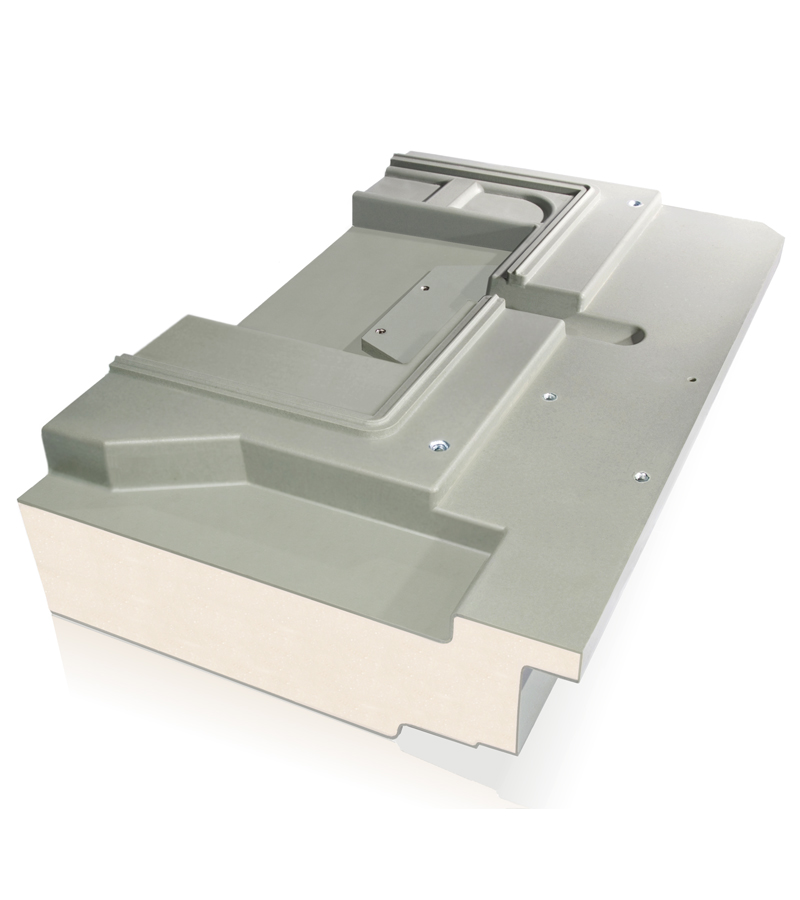

VASCA PELMO

Carùs expands its proposals for the refrigeration industry by introducing a range of bodies equipped with advanced and complete solutions.

Advantages

- Easy assembly of the cabinet

- Shorter cabinet construction times

- Reduced design times

- Excellent thermal insulation

- Easy end-of-life disposal

Details

- Integrated drain

- Inclination that facilitates the drainage of water

- Pipe passage ready

- Cable routing ready

- Base fixing ready

- Rack fixing ready

- Embedded supports for the top

- Easy installation of the bumper

- Made entirely in rigid polyurethane

- Modular height